The ESS Beam Diagnostics team, in collaboration with Oslo University, has recently installed mirrors in the Proton Beam Instrumentation Plug. Positioned between the Target Wheel and the Proton Beam Window, this diagnostic device reflects light from proton beams hitting the Target Wheel, providing a snapshot of the beam's footprint.

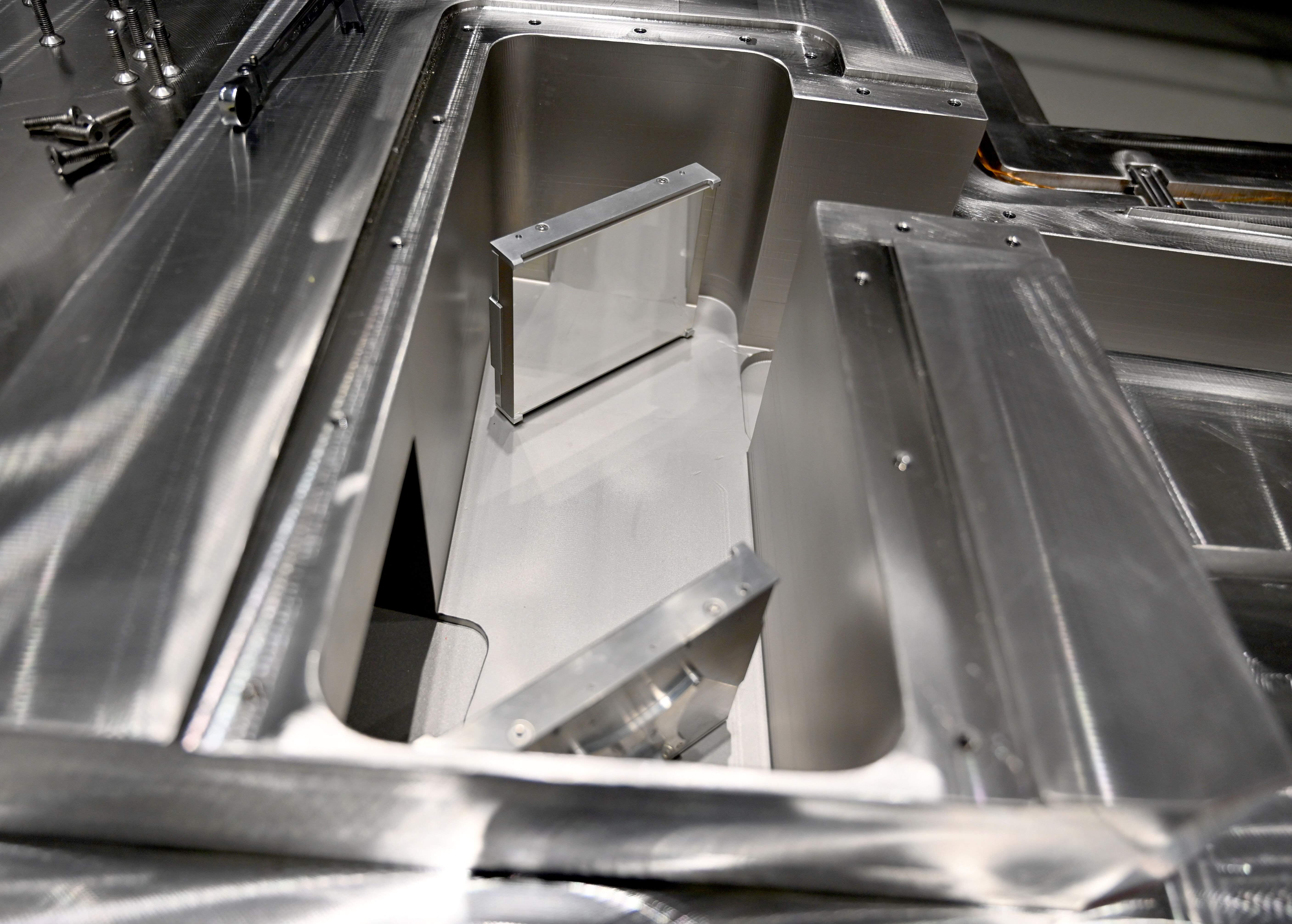

Last week, the ESS Beam Diagnostics team completed mirror installation in two slices of the Proton Beam Instrumentation Plug (PBIP).

This installation facilitates real-time monitoring of beam characteristics, crucial for maintaining operational efficiency and safety during initial beam tests.

The PBIP, situated in the Target Monolith vessel, comprises five 4-metre-tall slices, two of which are optical. Each optical slice contains mirrors, directing light from beam interactions onto cameras for diagnostics.

These mirrors reflect light from the proton beam as it enters through the Proton Beam Window and impacts the Target Wheel, allowing for precise snapshots of the beam's footprint. A luminescent coating previously sprayed on to the surfaces to be impacted by the beam will enable beam visibility. A sophisticated camera in the Accelerator to Target (A2T) access area takes snapshots at each pulse, 14 times per second, synchronized with the ESS global timing system. The system communicates directly to the Fast Beam Interlock System of the the Machine Protection System, ensuring beam quality control and the possibility to turn the beam off should the parameters not be as desired.

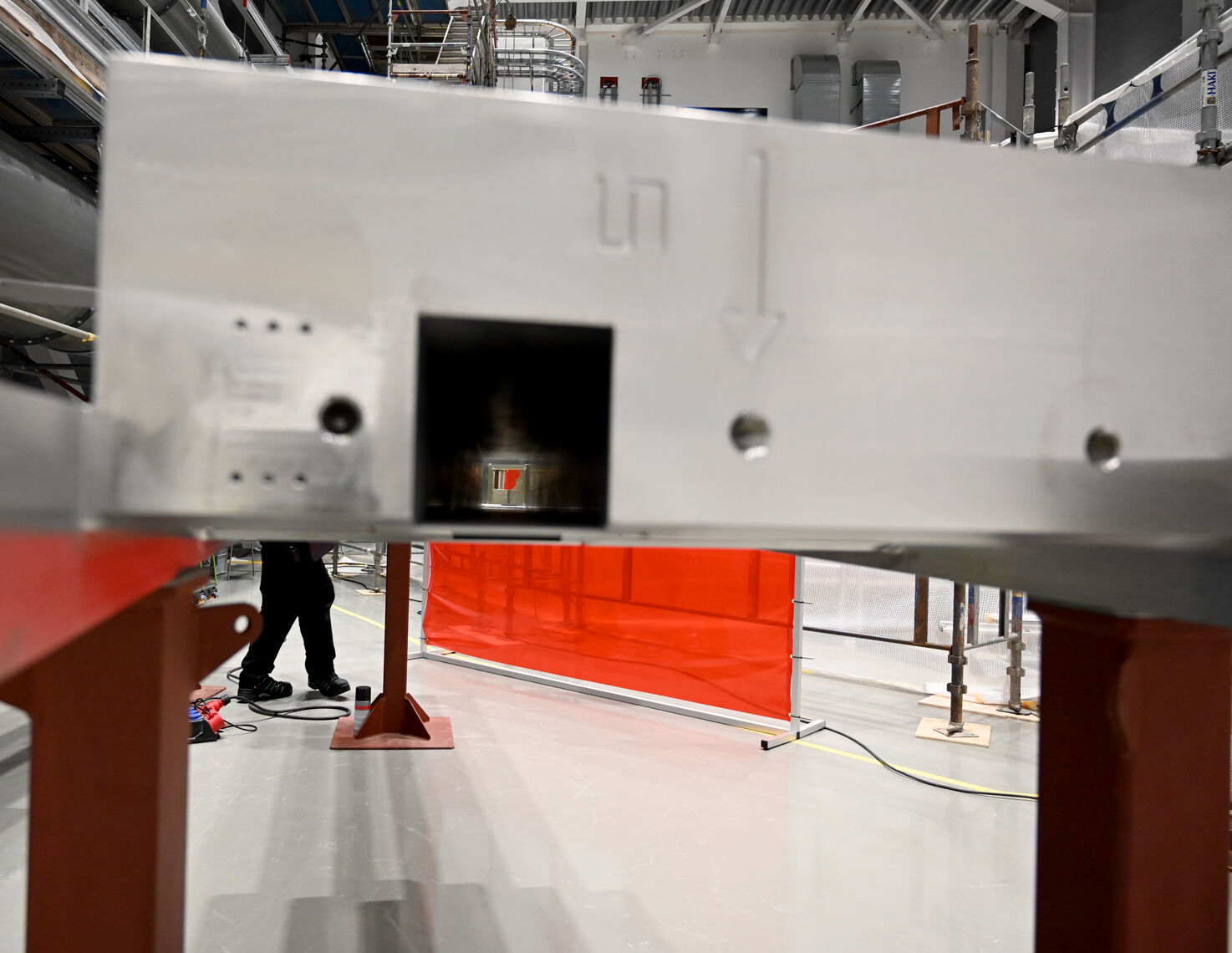

The first set of four mirrors are installed to reflect the beam pattern through the PBIP structure. The next step is to perform tests of the optics with a virtual target in the mock-up and test stand. The second part of the installation, connecting the duct and the mirrors reflecting the beam footprint to the camera, will be done at a later stage.

As part of the Norwegian In-Kind contribution to ESS, a prototype of the optical system was developed at Oslo University and tested at ESS. Engineers from Oslo University continue to be involved in the installation on site and the subsequent testing.

The PBIP and slices, along with other major technical components for the ESS Target, are part of the Spanish ESS Bilbao's In-Kind contribution to ESS.