Vacuum

The ESS Vacuum Group is responsible for all facility vacuum systems (including vacuum instruments and control systems) for the Accelerator, Target, and Instruments. The goal is to achieve an integrated vacuum system design with common components, reduced maintenance and training needs, fewer hardware spare parts, standardisation to lower costs, and simplified interfaces with other sub-systems.

Working closely with all partners across the project, the group promotes the use of shared vacuum solutions, equipment, and standards. A common standard has been established and is documented in the ESS Vacuum Handbook.

The ESS Vacuum documents – including the handbook, rules, and interface specifications – define the technical and operational requirements for vacuum systems across the facility. These apply to all ESS In-Kind Partners, suppliers, and third-party companies involved in vacuum-related deliveries.

Vacuum Handbook

- ESS Vacuum Handbook Part 1 – General Requirements for the ESS Technical Vacuum System

- ESS Vacuum Handbook Part 2 – Vacuum Equipment Standardisation

- ESS Vacuum Handbook Part 3 – Vacuum Design & Fabrication

- ESS Vacuum Handbook Part 4 - Helium Leak Test

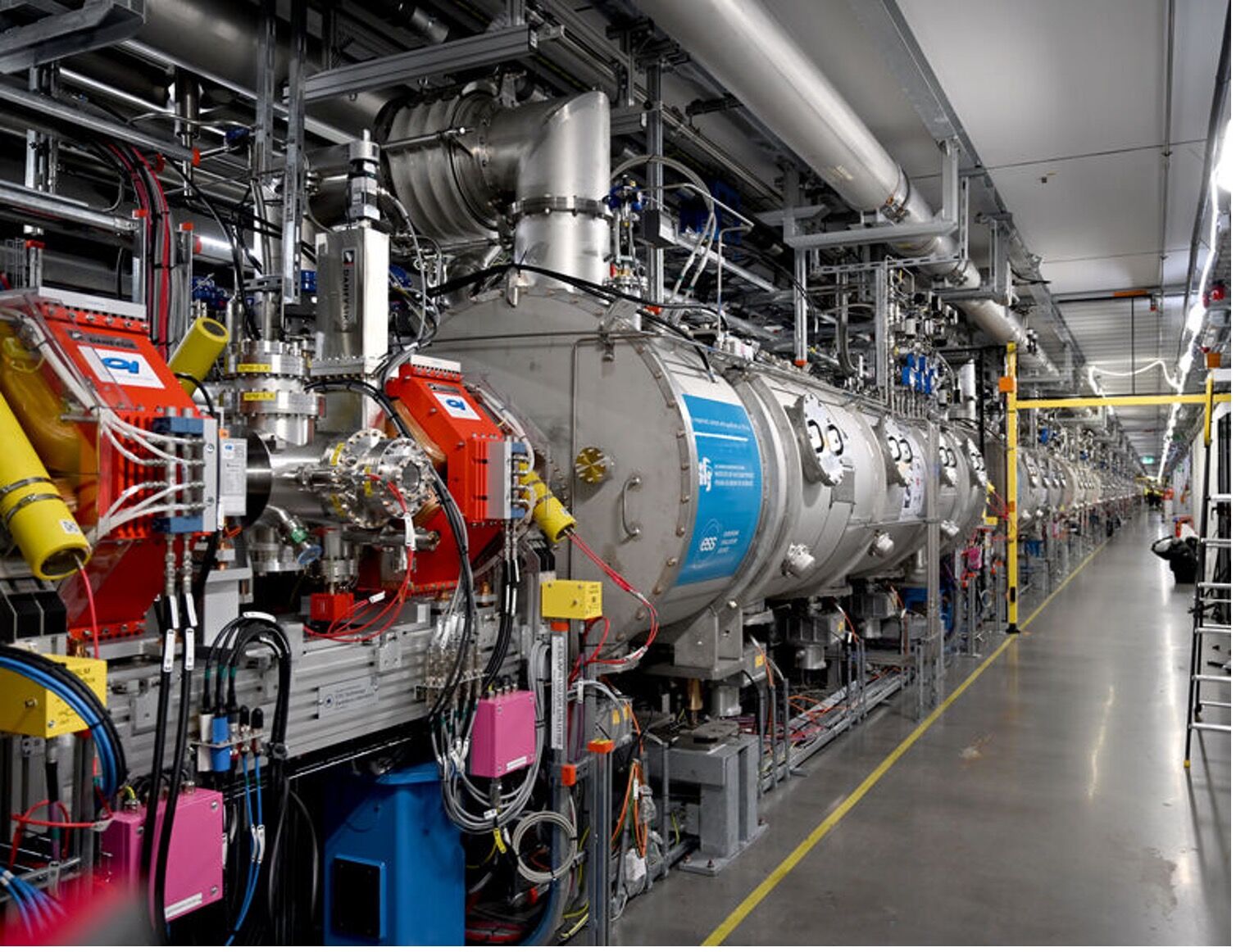

The accelerator vacuum system design incorporates conventional and unique solutions. Turbo-molecular pumps are planned for pumping down all sections, and depending on the location, permanent turbo pumps are used on the ion source, low energy beam transport, the radio frequency quadrupole, and at the end of the linac and the target monolith vessel. Other sections (Superconducting Linac) will be populated with combo-style pumps – a combination of small sputter ion pumps and low particle NEG pumps.

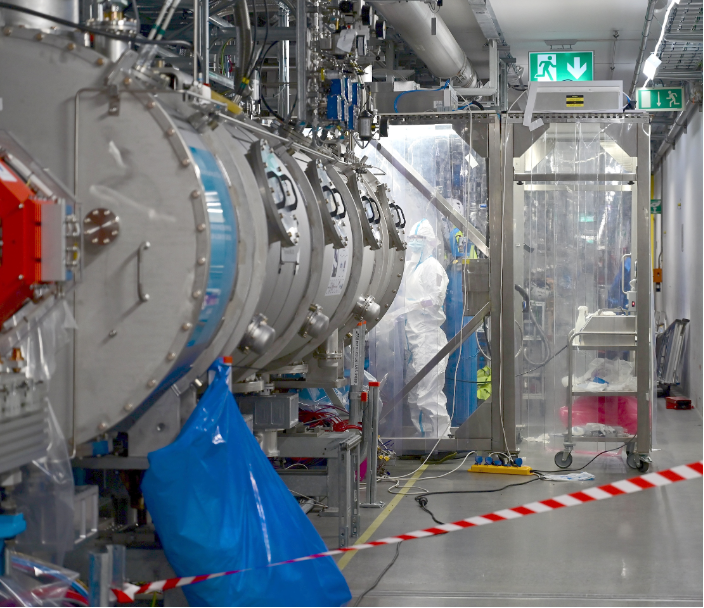

As with all accelerators incorporating superconducting technology, one of the critical features of the vacuum design is to minimise the gas load and particle generation to improve the reliability of long-term SRF cavity operation. The fabrication of the SRF components, such as gate valves and warm sections, and the assembly process of the vacuum connections in situ, were performed under cleanroom conditions (ISO 5/6) to minimise the potential for particulates being transported into the chambers and consequently into the cavities.

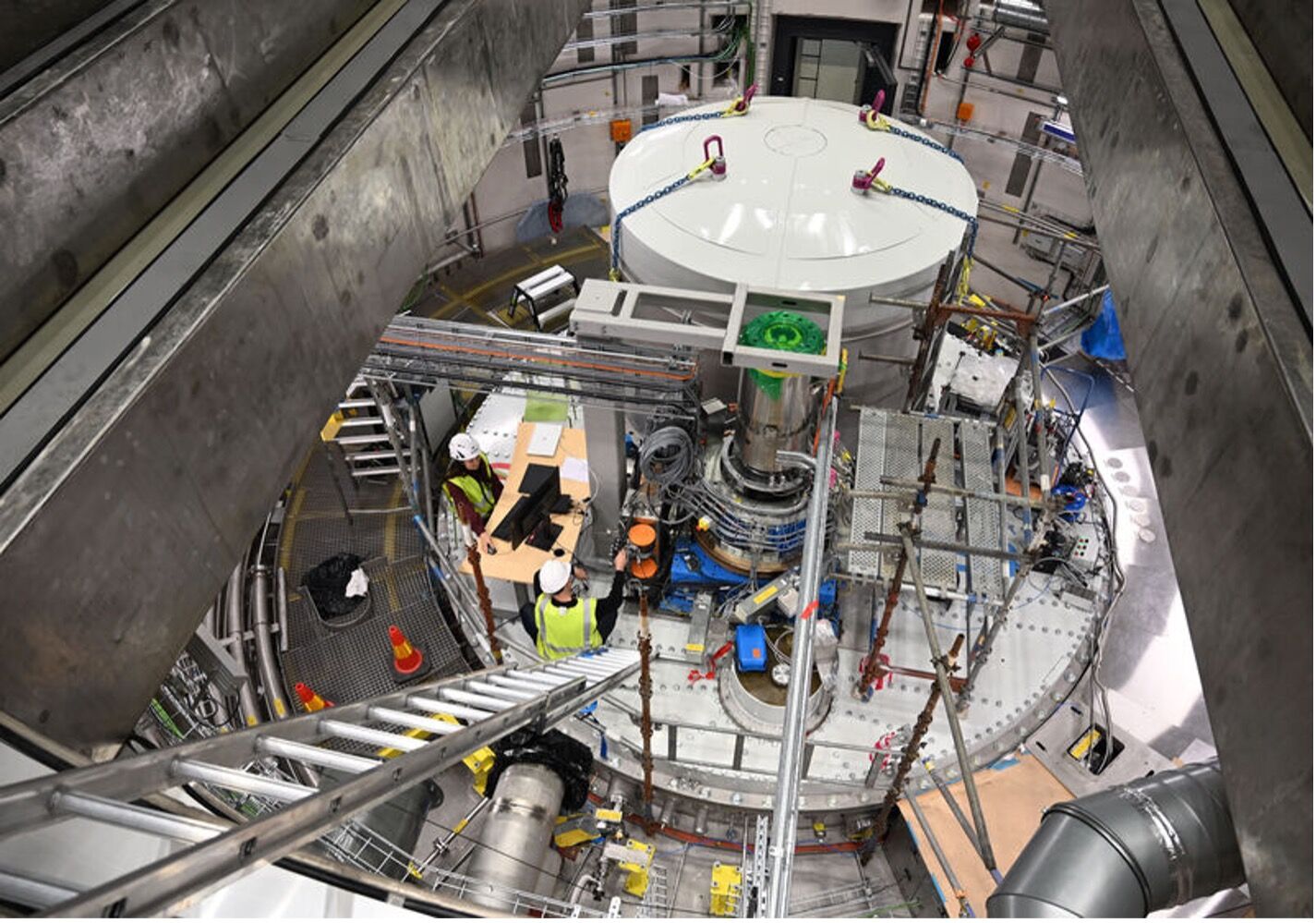

One of the most complex vacuum challenges is the Target Monolith vessel and the vicinity of the proton beam window interface (the physical barrier between the accelerator and the Target), where alignment, vacuum connections, water cooling, helium cooling for the wheel, and the liquid hydrogen moderator require specific solutions for reliable operation. These operations will be carried out remotely due to the anticipated residual radiation levels. Tens of thousands of bolts and hundreds of flanges must be assembled to high vacuum (HV) level or better.

The installation of the vacuum systems for the neutron instruments and neutron guides is an ongoing process as new instruments become ready. Each neutron experiment is a unique instrument, with vacuum requirements ranging from rough vacuum to ultra-high vacuum (UHV). Specifications cover several aspects, including high gas load (from cables, inner neutron shield coatings, and movable detectors), and fast pump-down from atmosphere to vacuum to allow quick access to detectors and a fast turnaround (1 hour) back to operational vacuum level.