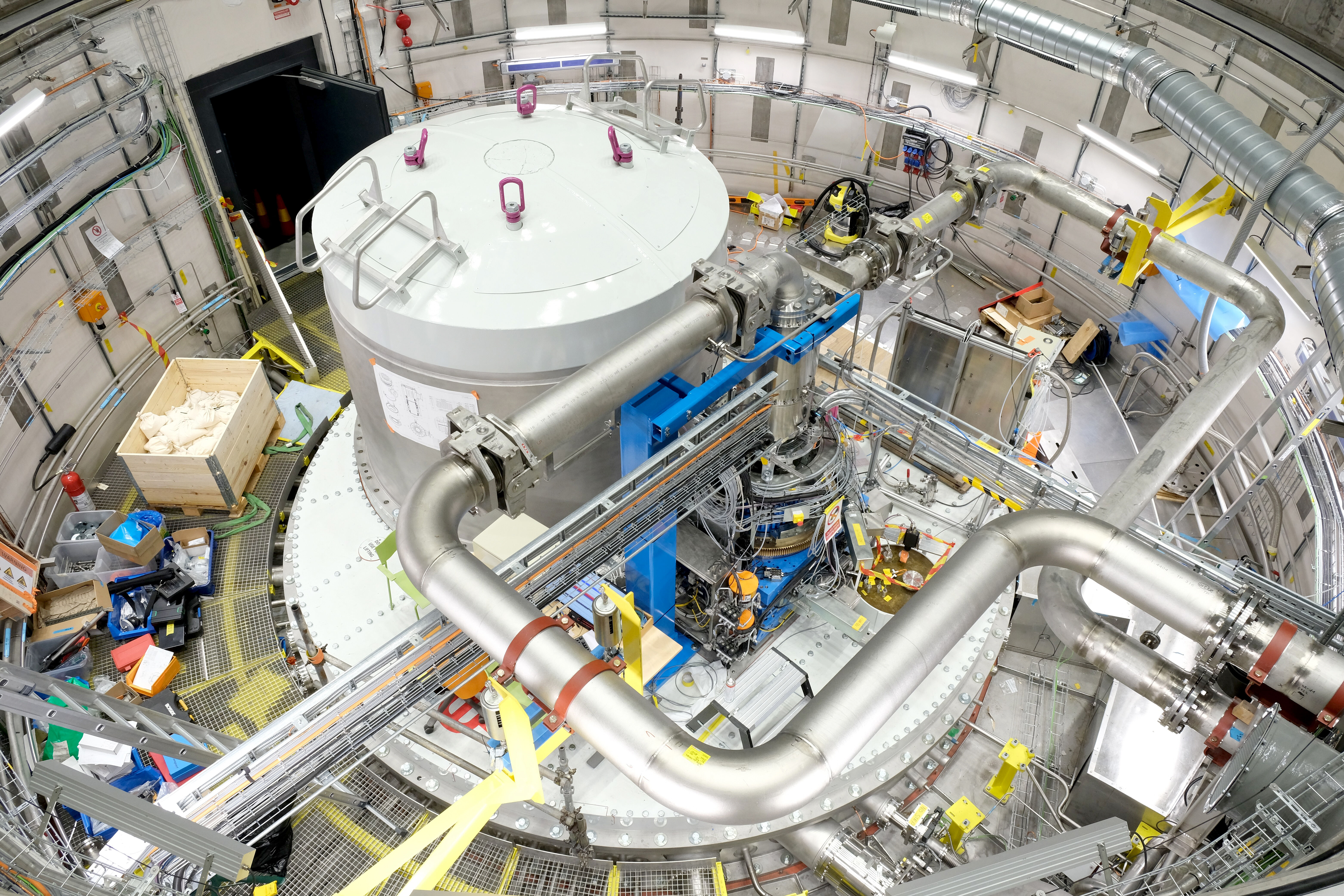

This week marks the start of 24/7 Neutron Factory tests in the ESS Target Station. These tests represent the first time all target systems are operated together as one integrated facility, a crucial step towards achieving Beam on Target in March 2026.

The Neutron Factory test phase will run continuously for the remainder of the year. During this period, the Target area and all its connected systems will be tested in full operational mode to ensure that every component, control system, and safety function work seamlessly together.

“The Neutron Factory tests are where all our efforts come together,” says Jaime Arriagada, coordinator of this crucial commissioning phase. “It’s the moment we prove that the entire Target Station can operate safely and reliably as one integrated system, ready to receive the first protons and produce the first neutrons.”

What the Neutron Factory Tests Include

The NF tests cover all systems that make up the Target Station and its supporting infrastructure:

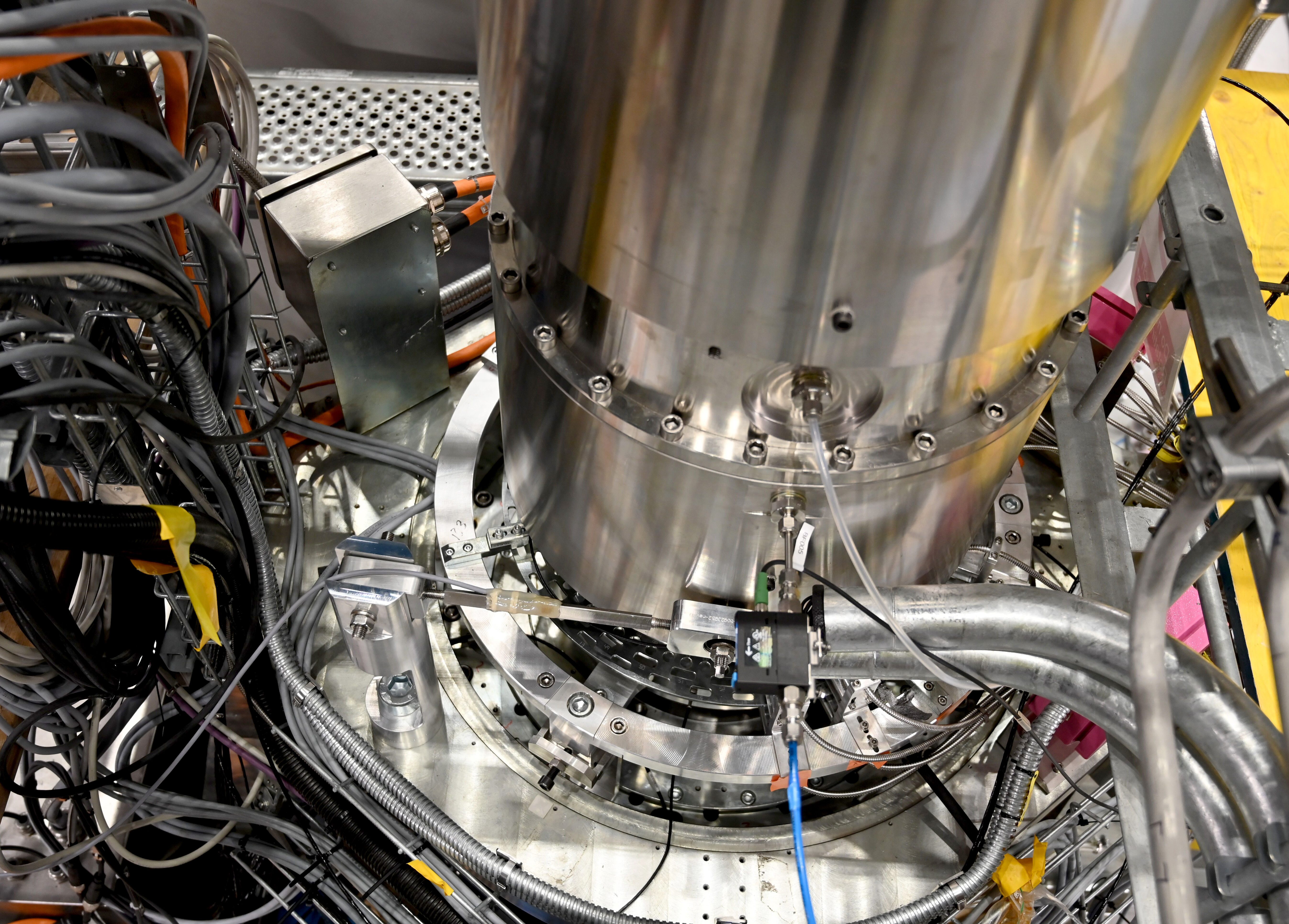

- Target Systems – all components related to the rotating target wheel.

- Moderator – systems for the moderator-reflector assembly.

- Monolith – inner shielding blocks, target monitoring, and beam instrumentation.

- NBEx – neutron beam extraction systems, including light shutters, helium atmosphere, and water cooling.

- HVAC System – building-wide heating, cooling, ventilation, and fire control systems.

- Target Safety System – the independent safety layer that automatically shuts off the beam if operational parameters fall outside safe limits.

Each of these systems has undergone individual and integrated testing. The Neutron Factory test now brings them all together for full systems operation under steady-state conditions.

Work on the Remote Handling system, which is not required for Beam on Target and includes the active cells and cask assemblies for safe maintenance operations, will continue in parallel and is planned for completion during 2026.

The Road to Beam on Target

In early 2026, the next step will be facility-wide system acceptance and safety readiness reviews followed by a period of continuous “soak testing”, during which the systems will run for several weeks to build operational experience and tune performance. These activities lead directly to the final regulatory permits required for Beam on Target.

Throughout this period, the tests also act as essential training for operators and technicians. Procedures, operational manuals, and safety interlocks are verified and updated, ensuring that the Target Station is prepared for continuous operation.

“With these tests, we’re validating every aspect of the Target Station’s operation and its integration with the accelerator and instruments”, explains Jaime Arriagada. “When we complete this campaign, we’ll have demonstrated that the entire system can run safely, stably, and continuously, the final proof we need before taking the step to Beam on Target.”